- Tension Springs

- Compression Springs

- Disc Spring

- DIN2093 Disc Spring

- Wire Forms

- Drawbar Spring

- Wave Washer

- Barrel Springs

- Thread Insert

- Spiral Springs

- Torsion Springs

- Die Springs

- Volute Springs

- Belleville Washers

- Taper Spring

- Helical Spring

- Coil Spring

- Heavy Duty Spring

- Solid Thread Insert

- Thread Repair Kit

- Slotted Disc Spring

- DIN6796 Belleville Washer

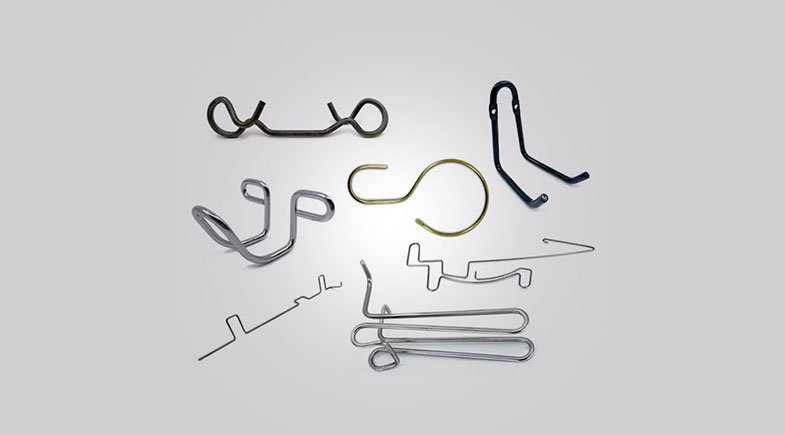

Wire Forms – The Ultimate Custom Component

About the Product

Wire Forms are **custom-bent metal components** designed to fulfill applications requiring a specific force, positional control, or mechanical linkage that a standard helical or conical spring cannot provide. They are the go-to solution when your design demands a highly flexible, non-standard shape.

- Virtually **infinite design possibilities**

- Precise bending and forming for complex 3D shapes

- High strength-to-weight ratio

- Cost-effective for high-volume manufacturing

Wire forms are used extensively across all major industries, including **automotive latches, consumer electronics, medical devices, and construction hardware**. If a component needs to clip, latch, brace, or position another part, a custom wire form is often the most economical and reliable choice.

Technical Specifications

Characteristics: Complex 3D shapes, high precision, and custom load characteristics based on design.

Measurements: Wire Diameter: 0.1 {mm} – 16 {mm}. Length and Form: Fully customizable to blueprint specifications.

Configurations: Custom end configurations (loops, hooks, eyes, or cut-off ends), available with zinc, powder coating, or chrome plating.

Rate or Stiffness: Highly variable (5–200 {N/mm}), dependent on wire diameter, bending radii, and leverage.

Service Life: Design-dependent, capable of up to 1,000,000 cycles under optimal load conditions.

Tolerances: Tight control: pm 0.05 {mm} on wire diameter and pm 1^{\circ} on bending angles.

Applications: Automotive latches and linkages, medical guidewires, furniture springs, electrical clips, and fasteners.

Ready to discuss your custom spring requirements? Contact us now