- Tension Springs

- Compression Springs

- Disc Spring

- DIN2093 Disc Spring

- Wire Forms

- Drawbar Spring

- Wave Washer

- Barrel Springs

- Thread Insert

- Spiral Springs

- Torsion Springs

- Die Springs

- Volute Springs

- Belleville Washers

- Taper Spring

- Helical Spring

- Coil Spring

- Heavy Duty Spring

- Solid Thread Insert

- Thread Repair Kit

- Slotted Disc Spring

- DIN6796 Belleville Washer

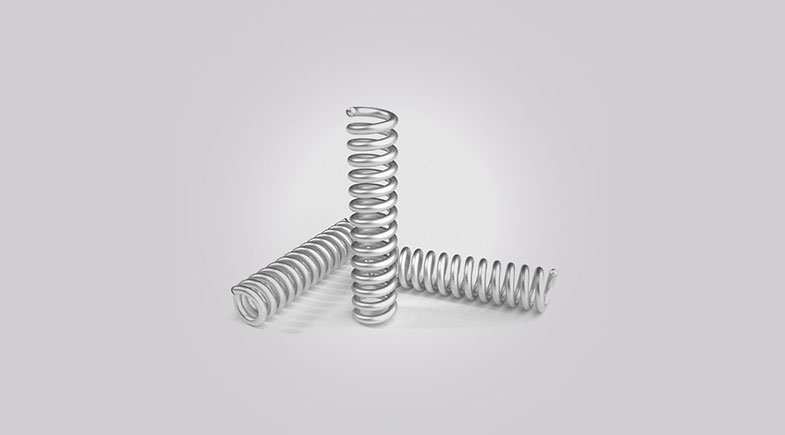

Heavy Duty Spring – Power and Reliability under Pressure

About the Product

Our Heavy Duty Springs are specifically engineered for applications that involve extreme loads, high temperatures, and continuous operational demands. Typically manufactured from high-tensile alloy steel with wire diameters exceeding 15 mm, these springs are the backbone of systems in mining, railway buffers, heavy construction, and large industrial presses. Their design prioritizes longevity and resistance to permanent set under monumental static or dynamic forces.

- Designed for continuous operation under extreme static or dynamic loads.

- Manufactured using hot coiling for superior stress relief and strength.

- Excellent resistance to fatigue, creep, and permanent deformation.

- Customizable configurations for high-temperature and corrosive environments.

Darshan Heavy Duty Springs are not stock items; they are custom-designed to fit specific load requirements and space constraints of critical infrastructure. We work closely with our clients in the railway and heavy machinery sectors to determine the exact spring rate, material grade (such as Chrome-Silicon or 300 series stainless steel), and protective coatings needed to ensure years of trouble-free operation in the most demanding conditions.

Technical Specifications

Characteristics: Large diameter compression springs, often using ground ends and specific load-bearing surfaces.

Measurements: Wire Diameter: 15 mm – 60 mm. Outer Diameter and Free Length are highly customized.

Material: High-tensile spring steel (e.g., 51CrV4), Chrome-Silicon (for high heat), and specialized alloys.

Key Parameters: Maximum Load (up to 200 kN), Solid Height, Fatigue Life Cycles.

Manufacturing Process: Hot-coiled and stress-relieved to handle thick material sections.

Unit of Measure: mm, kN (Kilonewton).

Coating and Finish: Black Oxide, Zinc Phosphate, or heavy-duty epoxy coatings for corrosion protection.

Applications: Railway suspension and draw gear, heavy industrial machinery, safety relief valves, high-pressure equipment.

Ready to discuss your custom spring requirements? Contact us now